Decking Repair and Replacement

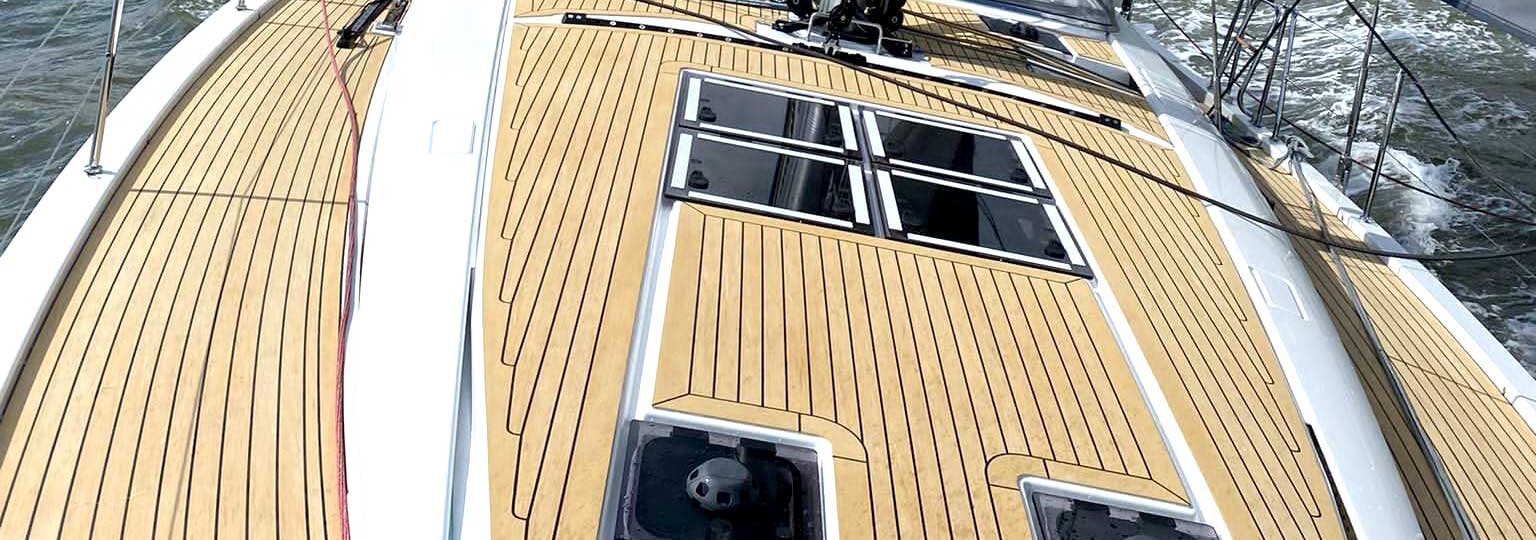

Natural Wood Decking – Teak / Iroko

Need new natural wood decking, a repair or complete restoration? Look no further. With decades of experience working on teak decks, we have the specialist skills required to produce long-lasting beautiful decks that will withstand the test of time whether you are racing, ocean sailing or day cruising. We source the best quality timber, weather Teak or Iroko, from sustainable forests all FSC Certified.

Synthetic Decking – Flexiteek

As the south coast’s exclusive Flexiteek installer for yachts between 35-75ft we now offer the full range of products including the new Flexiteek3 created using a using a bio-attributed PVC. This product is available in a wide range of colours, manufactured into planks and sanded before being welded together to create a strong and durable bond. The result is a very realistic-looking substitute that is long-lasting, whether-resistant and low maintenance.

Teak Decking

Need new teak decking, a repair or complete restoration? Look no further. With decades of experience working on teak decks, we have the specialist skills required to produce long-lasting beautiful decks that will withstand the test of time whether you are racing, ocean sailing or day cruising. We source the best quality teak possible from sustainable forests.

Benefits of Teak

- Long lasting durability

- Incredible resistance to all kinds of weather

- Natural antimicrobial substances prevents against rot

- Ability to fair panels for a perfect fit

- Good non-skid properties

- Stays warmer in colder climates

- Provides extra insulation

Flexiteek

Flexiteek is a synthetic alternative to real wood teak decking. Made from 2G polymer pellets, it is manufactured into planks, sanded to bring out the grain and then vinyl welded together to create a strong and durable bond. The result is a very realistic-looking substitute that is long-lasting, weather-resistant and low maintenance.

Benefits of Flexiteek

- Looks like real teak

- Long lasting (10 year guarantee)

- UV resistant

- Slip resistant

- Low maintenance

- Easy to clean

- Over 30 colour combinations

- Lighter than rival synthetic decking

- Bespoke options including embedded logo / boat name

Why use Ancasta Yacht Services?

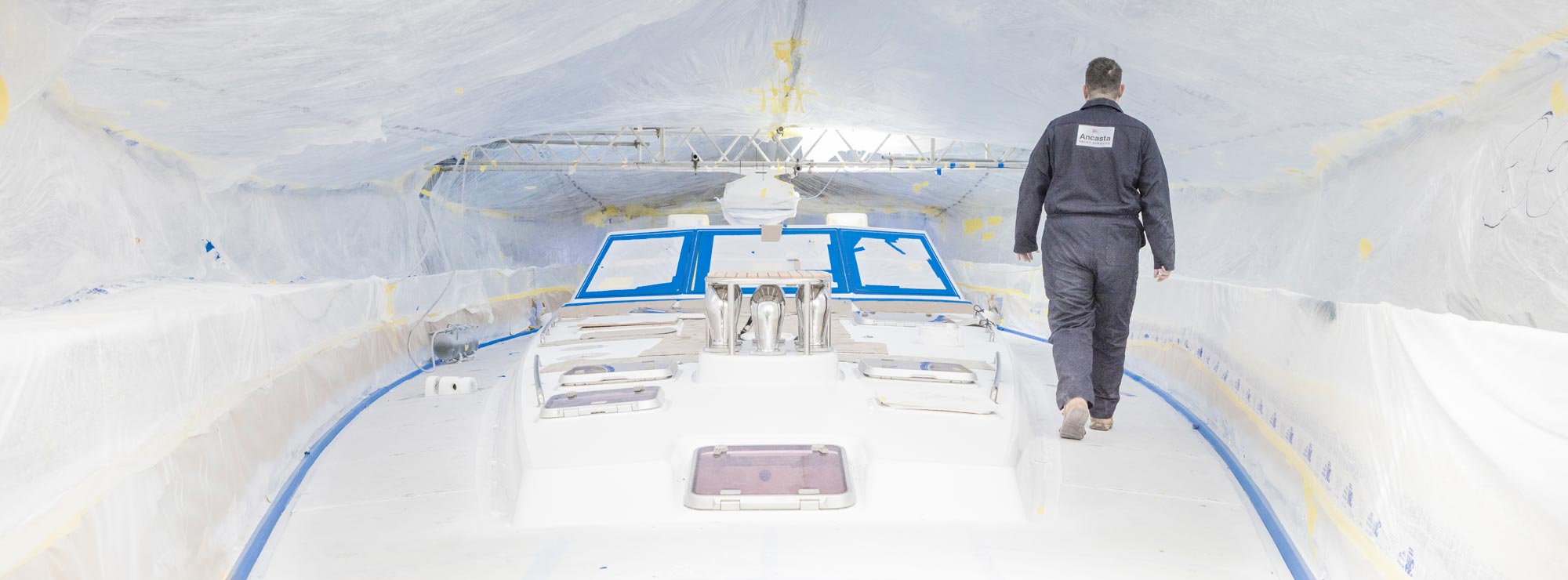

Undercover Workshops

We have three sizeable bays in our huge sheds in the Hamble Yacht Services boatyard. This allows us to keep your yacht undercover when the deck is being repaired or replaced, giving you significant cost savings by eliminating the need for a full shrink-wrapped tent outside (and reducing unnecessary plastic use) and avoiding unnecessary delays caused by the weather. We can build staging around the boat inside our sheds to provide easy access to the decks if required.

Modern Teak Laying

Modern teak deck layouts tend to have fewer joins than older ones, meaning our teak and joinery team can lay up custom built teak panels to reduce time and therefore cost.

Making templates of the deck areas out of 6mm MDF, the teak is then laid out and caulked together in the workshop before the panel is glued onto the deck in one piece. This process is much quicker than conventional methods and produces a neater finish due to increased control and better working conditions - it is much easier to lay the planks and margins on a workshop table than on the yacht itself.

The side deck panels, however, are laid directly onto the deck using pre-rebated strips of teak which are pulled into the sheer of the yacht using special clamps. It is also possible to apply teak without the rebate and with full depth seams.

Precision Teak Fitting

The biggest challenge for the team when laying a new teak deck is making sure that the teak looks symmetrical. The very nature of boats means that their decks are never 100% symmetrical, especially when there are hatches and deck fittings to work around. So, we take care to lay the panels with the utmost precision. This sometimes means shaving just 1mm off each piece of wood to reduce a margin across the whole width of the panel to make sure it matches on both sides of the yacht. Care is also taken to ensure that placement of the snape joins are uniform and follow the natural flow of the deck. Butt joins are hidden under deck fittings where possible, and long planks are used to reduce the number of joins on show.

The Finishing Touch

Once the teak panels are complete, they are fixed in place using sikaflex 298 bedding compound and vacuum bagged down to create a secure bond. The use of sikaflex instead of epoxy allows the decking to breathe and flex with the boat and helps avoid any spill damage to other parts of the yacht. The deck is then left for two weeks to cure before the team sands it back to 80 grade grit with orbital sanders and the deck fittings refitted.

Skilled Joiners

Adam is the Ancasta Yacht Services Boat Building Team Leader, he has boatbuilding in his blood with his father a cabinet maker, his uncle a boatbuilder and his grandfather was a steelworker on ships. Living by the sea, Adam tells us that working on boats was the most natural thing for him to do, and he is proud to continue his family trade. Having has learnt his skills from the best, he has laid teak decks for over 2 decades. Backed up by a large team of skilled boat builders and joiners, we take pride in every project we take on.

Ancasta Yacht Services Ltd

Port Hamble, Satchell Lane, Hamble, Southampton, SO31 4NN

Ancasta Yacht Services is based on the picturesque banks of the River Hamble in the UK with direct access to Southampton Water and the Solent.

The Port Hamble site features covered workshops for yachts up to 26 meters, an engineering workshop, wood and laminating facilities, and a joinery shop.

Ancasta Yacht Services: