- Make McConaghy Boats

- Model MAKARA 85

- Year 2024

- LOA 83ft/25m

- Class Sailing Cruiser

- Hull Carbon Fibre

- Keel Fin Keel

- Rig Sloop

- Engine Single Diesel

- Drive Shaft Drive

- Layout Aft Cockpit

- Berths 8

- Cabins 4

- Ancasta Ref 36323

- Name MAKARA 83

McConaghy Boats MAKARA 85 | 2024

Designed to glide with the lightest of breeze, the Makara 85 delivers the highest levels of sailing performance with minimal effort and maximum comfort.

This exceptional collaboration from Malcolm McKeon Yacht Design and McConaghy Boats awaits your input to deliver the yacht of your dreams.

NAVAL ARCHITECT: Malcolm McKeon Yacht Design

BUILDER: McConaghy Boats

COMPOSITE ENGINEERING: Pure Design & Engineering

DIMENSIONS

LOA - 25.90m

LWL - 24.60m

BEAM - 6.35m

DRAFT - 4.50m

DISPLACEMENT - 48 Tons (Light) 54 Tons (Full)

General Vessel Construction

• Vessel structure built to DNVGL

• Hull, Deck, Cabin top & Structure are built with high performance structural foam cores carbon prepreg

• Carbon composite strap chain plates integrated into the hull structure

• Fixed Fin keel with lead bulb

• Carbon fibre rudder stock and blade with JP3 bearings

• Carbon prepreg Bowsprit w/ optional rod bobstay

Composite Finishes

The hull and superstructure shall be painted with the owner’s

selected colour in urethane paint. Dark colour not recommended, non-metallic paint allowed for only

• Fairing and paint will be applied as per Manufacturers specification

• All bilges are painted with epoxy paint

• All fuel, water and black/grey tanks shall be epoxy coated with coating suitable for the use

* all dimensions & weights are approximate

I - 31.50m

J - 9.87m

P - 30.50m

E - 11.10m

Mainsail Area - 189 sqm

Furling Blade - 149 sqm

Furling Staysail - 98.75 sqm

SOUTHERN SPARS MAST & BOOM

• Rig layout to be an aft swept, 4 spreader configuration supported

by a centreline backstay for a pinhead mainsail

• Mast tube laminate in Standard modulus carbon fibre, with standard modulus spreaders.

• Provision of the following sheave layout near mast head(p3):

• One (1) 2:1 Main Halyard

• One (1) 1:1 MH Spinnaker halyard sheave - Inline above code sheave

• One (1) Code halyard sheave - Incline below spinnaker sheave

• Staysail to be a removable furling sail hoisted and locked into a spigot tang.

• Blade 1:1 halyard terminated on halyard rack.

• Southern Spars deck stepped mast base system with external hydraulic jacking function.

BOOM

• Box wing boom with hydraulic mainsheet ram

• Allowance for three reefing lines

STANDING RIGGING

• Complete Ni50 rod lateral rigging package with stainless steel clamp tangs, seats and miscellaneous fittings to designer’s specifications

• Backstay and Checkstay cables to be K49 Kevlar

• All stays complete with stainless steel end fittings

• All Ni50 rods to be polished finish

• Aft rigging K49 Kevlar cables covered in black plastic jackets

• PBO Staysail Stay and Code sail torsional luff cables to be supplied within the sails by the sail maker

RUNNING RIGGING supplied for main and self tacking blade

NORTH SAILS

• Full Batten Mainsail 3Di OCEAN 700 32,000 Dpi

• Self Tacking Blade 3Di OCEAN 700 35,000 Dpi

• Harken 32mm T track cars, Cunningham, intermediates, battens and toggles

• CTECH Full length battens

WINCHES & RAMS

• 1 x hydraulic control reverse purchase mainsheet ram

• 1 x Harken reverse purchase ram for self tacking blade or staysail

• 2 x Harken primary winches

• 2 x Harken mast base winches

HARKEN SAILING HYDRAULIC SYSTEM

• 1 x reverse purchase system ram in boom

• 1 x reverse purchase system self tackers

Hydraulic manifolds for:

• 1 x Manifold for Mainsheet

• 1 x Manifold for Self Tacking Blade

• Boom vang

• Stern platform

• Four harken winches

• 1 x Reckmann blade furler

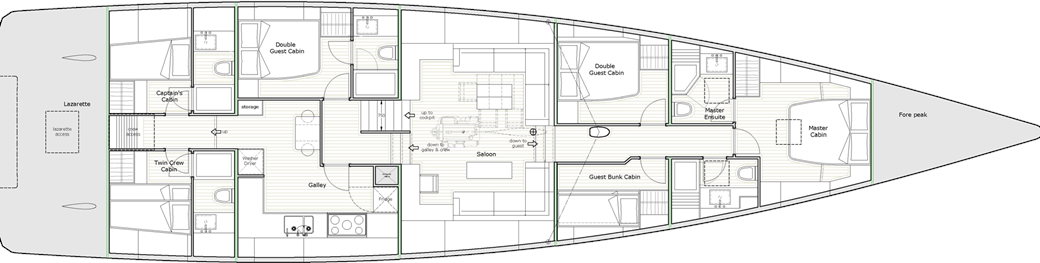

Three cabin or four cabin plus crew

The four drawings attached show options with Master Cabin forward or aft, various guest cabin arrangements and various grew cabin arrangements.

Interior General Information

Interior Surfaces

• All joinery is built and finished to McConaghy Boat high quality finish

• The modern interior is constructed using a mix of painted surfaces with high quality timber leathers soft fabrics

Appliances

• Isotherm Draw freezer 160L

• Isotherm Draw Fridge 190L

• Miele convection oven

• Miele induction hub

• Miele microwave

• 1 x Ice maker

• 1 x Washer and dryer

In general, access to the machinery and pumps is carefully taken into account during the build process. Removable panels are provided to allow service access to all systems, valves, junction boxes, etc

• All vibrating or moving items are, as far as is practical, fitted on anti-vibration mounts. All vital equipment such as bilge pumping, fire-fighting equipment, transfer of fuel, freshwater, black water, has the provision to work from a second reserve pump in order to ensure maximum safety

• All pipes in the machinery space are polished, painted or plastic coated and marked with the system number. Labels are used to show the direction of flow and the contents of the pipes. Pipes carrying cooled or heated liquids are insulated as appropriate

• Pipes are laid out where possible along the centreline under the floor and orthogonally, flow restrictions are minimised and care taken to ensure that drain points are accessible

• Clamps bolted to the structure will support them and in accommodation space they will be isolated from the pipe hangers with nylon, or equivalent, saddles. Where pipes pass through a watertight bulkhead the penetration will be watertight. All valves are individually identified and pipe and valve names are shown on the system diagrams

Engine Room

• Engine room mid ship will be painted and lined with soundproofing

• Delta T fans in engine room with 24V control system

• Two Delta T fire damper systems in engine room

TANKS (Preliminary)

• Fuel Capacity 3,500 Lts

• Fresh Water Capacity 2,000 lts

• Grey & Black Holding Tank Capacity 1,000 lts

• Diesel fuel: Vessel to have 2 separate tanks with separate fills for each tank. Transfer system shall transfer fuel between tanks

• Fresh water tanks: Transfer system between fresh water tanks

• All tanks will be labelled with type and capacities. All tanks shall have

inspection access hatches and baffles

Fills & Vents

• Fills: Fuel: (4) 2” SS flush mount fill

• Water: (2) 1 ½” deck fills

• Vents: Black water and fuel vents routed up the mast

• Black and grey water pump outs to be furnished for

ENGINE

• 1 x Yanmar diesel engine 195hp

• Gearboxes

• Electric throttle control system

• Conventional shaft with PPS seal

PROPELLER

• 1 x folding propeller

• Generator: (1X) 27 kW

FUEL SYSTEM

• Fuel tanks are built into the structure

Fuel Transfer Pump

• The fuel is led via valves to a transfer pump and uses a Mahle FTS 1200 fuel polishing system

Fuel Gauges

• Individual (one for each tank) fuel tank electric level system with control panel in nav station. Manual gauging access also provided

Fuel Filters

FRESH WATER SYSTEM

Water maker System Optional

Fresh Water Pumps

• Calpeda fresh water pumps

Hot Water Tanks

• One 120 litres hot water cylinders will run through one hot water circuit. One Calpeda circulation pump will be used to keep hot water at the outlets and conserve water. The cooling circuits from generator will be used to heat the hot water

Fresh Water Hose Bibs (exterior)

• Cold water; SS taps:(1x) on the fore deck and (1x) one on transom

• Fuel filter/water separator systems for engine and dual fuel filter/ water separator for generator

BLACK & GREY WATER SYSTEM

• Tecma Privilege Toilets x 5

Suction Pump Optional (Overboard Pump Out-standard)

Sump Pump

• Two grey water sump pumps, One Tortuga diaphragm pump or equivalent will be used to pump black/grey water tanks overboard through an overboard fitting in the hull. (Water maker water

(optional) will come from the sea chest on either side while grey and black will be pumped out on the either)

Black/Grey Water Tanks

• Black/Grey water tanks will have charcoal filter on vents or up the mast

Bilge System

• One bilge pump for each watertight bilge compartment with manual and automatic switches. Compartments also include a high water level alarm. Bilge pumps and high level alarms are monitored by ships monitoring system

Emergency Bilge

• 2 x backup bilge pumps – 35 l/min

FIRE FIGHTING SYSTEM

Where practicable, extinguishers will be placed in concealed spaces (cabinets, pockets, etc.) with proper mounting (owner supply)

Fire Suppression System For Engine Room

• Automatically or manually activated Firebuoy. Activation automatically stops engines, generators and ventilation. Manual reset button allows systems to restart

CENTRAL HYDRAULIC SYSTEM

• 1 x Reservoir

• 1 x heat exchanger

• 1 x genset piston pump

• 3 x value bank assembles 8 function each with pressure and flow control

• 4 x logic valves pump outlet

• 4 x pump solenoid logic valves

HVAC

• Air conditioning package with total of 140k BTU, total of 8 x air handlers

ELECTRICAL

• 24V Power Supply

• One (1) Galvanic Isolator

• One (1) 110Amp 24V alternators

• One (1) 12V 120AH AGM Main Engine Start Batteries

• One (1) Generator start battery

• 6 x 180AH lithium ion batteries

• CZone Digital Switching System including; touch screen, iPad compatible, voltage, tank, bilge and fuse alarms, lighting (switches and dimmers)

• Remote battery switches under nav station

• Reading lights

• Down lights

• Cockpit Lights

• Courtesy lighting

• Coach roof overhang discreetly lit with LED lights

• One (1) Red/White Nav Stn Light

• One (1) all round white nav.light

• One (1) stern light

• One (1) port light

• One (1) stbd light

• One (1) masthead light

• One (1) Tank Sensor Monitor

• AC switch panel

• Shore power, cables

• 2x Mass Combi Pro 24/3500-100 inverters

Hatches, Deck Lockers and Glazing

• High standard, custom McConaghy flush hatches, with concealed hinges and lockable latches fitted throughout

• Windows, Portlights, saloon doors – Eurogrey

Custom Metal Work

• All bright stainless will be all 316L, all high load stainless will be a grade of Aquamet and deck hardware stainless will be A3 or equivalent

Exterior Upholstery

Sunbrella or equal. Foam quality,thickness and density subject to owner approval

Deck Finish - Flexiteak

• The Aft deck, side deck, forward deck, planed teak battens with margin boards

TRANSOM DOOR / TEAK BEACH - providing access for tender, dive gear and toy storage.

STANCHIONS

• If stanchions required, they will be composite built, as per McConaghy standard

• If lifelines required, they will be wire (5mm, 7 strand) rope if class allows

ANCHORING

Fore Peak over rotating anchor arm concealed in fore peak hatch

1 x Lewmar V8 windlass

• 1 x CQR 140lbs galvanized bow anchors with 100m of 13mm galv chain

• 1 x manual chain stopper and storm anchor lashing points

CLEATS

On each side of the vessel there will be 4 cleats - two forward and two aft

SALOON AFT DOOR: custom, sliding door with glass panels. Door to be manually operated

Don't have an account? Register